LAM 853-801876-015 刻蚀机

产品概述:

853-801876-015命令停机包括以下停机,这些停机在维修工具中单独标识:853-801876-015停机-离散低功率备用停机-RS-853-801876-015232停机内部故障包括以下停机,在维修工具中单独标识:关闭-所有需求失败关闭-A/D转换器错误关闭-位置传感器失败关闭-当前Fdbk失败关闭-配置错误关闭-校准错误关闭-看门狗超时

主要或备用需求故障包括(在维修工具中单独标识):报警--模拟输入故障报警--PWM频率错误报警--PWM占空比错误报警--脉宽调制无信号报警--Can总线断开错误报警--Can Dmd无信号报警-Can Dmd过慢报警--跟踪错误内部故障报警包括(在服务工具中单独识别):853-801876-015报警-温度传感器故障报警--12V故障报警--Neg9V故障报警--5V故障报警--参考电压错误报警--软件错误报警--EEPROM错误。

Commanded Shutdown includes the following shutdowns, which are individually identified in the Service Tool: Shutdown—Discrete In Low Pwr Standby Shutdown—RS-232 Shutdown Internal Failure includes the following shutdowns, which are individually identified in the Service Tool: Shutdown—All Demands Failed Shutdown—A/D Converter Error Shutdown—Posn Sensor Failed Shutdown—Current Fdbk Failed Shutdown—Configuration Error Shutdown—Calibration Error Shutdown—Watchdog Timeout

Primary or Backup Demand Fault includes (individually identified in the Service Tool): Alarm—Analog Input failure Alarm—PWM Freq Error Alarm—PWM Duty Error Alarm—PWM No Signal Alarm—Can Bus Off Error Alarm—Can Dmd No Signal Alarm—Can Dmd Too Slow Alarm—Tracking Error Internal Fault Alarm includes (individually identified in the Service Tool): Alarm—Temp Sensor Fault Alarm—12V Fault Alarm—Neg9V Fault Alarm—5V Fault Alarm—Reference Voltage Error Alarm—Software Error Alarm—EEPROM Error

The diagnostics messages are transmitted at a rate of once per second. This message is sent only when there is at least one active fault or in response to a request from the speed control. All the diagnostic and event bits are set appropriately to indicate their current status. The speed control will decode the bits and display the corresponding diagnostic and event codes. The speed control also logs the diagnostic and event codes as required by the application. The speed control makes the decision to shut down or run depending on the application configuration, unless the ProAct actuator has already shut down. The decision will be based on the diagnostic and event classification made in the diagnostics document.Set 1 Incoming CAN Commands This section lists all messages, which will be sent by the speed control to the ProAct actuator. The PGN for commanded position must be different for each ProAct actuator and is determined by the ProAct CAN address harness.

853-801876-015诊断消息以每秒一次的速率传输。只有当至少有一个激活的故障或响应来自速度控制的请求时,才会发送此消息。所有的诊断和事件位都被适当地设置,以指示它们的当前状态。速度控制将对这些位进行解码,并显示相应的诊断和事件代码。速度控制还根据应用程序的要求记录诊断和事件代码。速度控制器根据应用配置决定关闭或运行,853-801876-015除非ProAct执行器已经关闭。决策将基于诊断文档中的诊断和事件分类。Set 1 Incoming CAN Commands(设置1输入CAN命令)本节列出了速度控制器将发送到ProAct执行器的所有信息。853-801876-015每个ProAct执行器的指令位置PGN必须不同,并且由ProAct CAN地址线束确定。

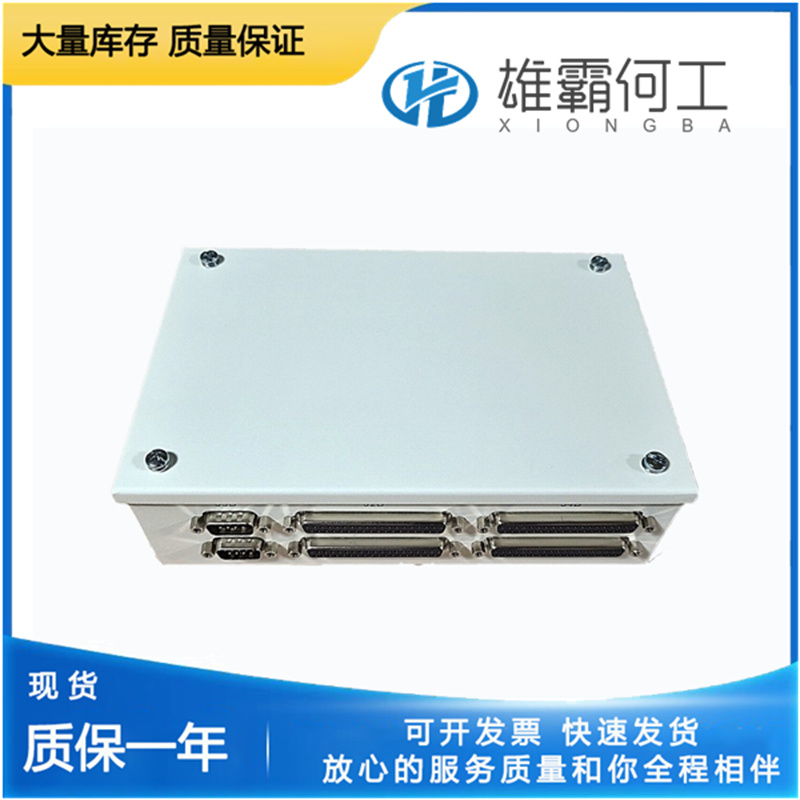

853-801876-015维修工具软件用于配置、调整ProAct并对其进行故障排除™ 致动器。本章介绍维修工具的安装和使用。它确定了ProAct产品中可用的Servlink参数,可以使用维修工具查看这些参数。它还提供了有关配置和设置ProAct执行机构以满足客户特定现场应用的详细信息。

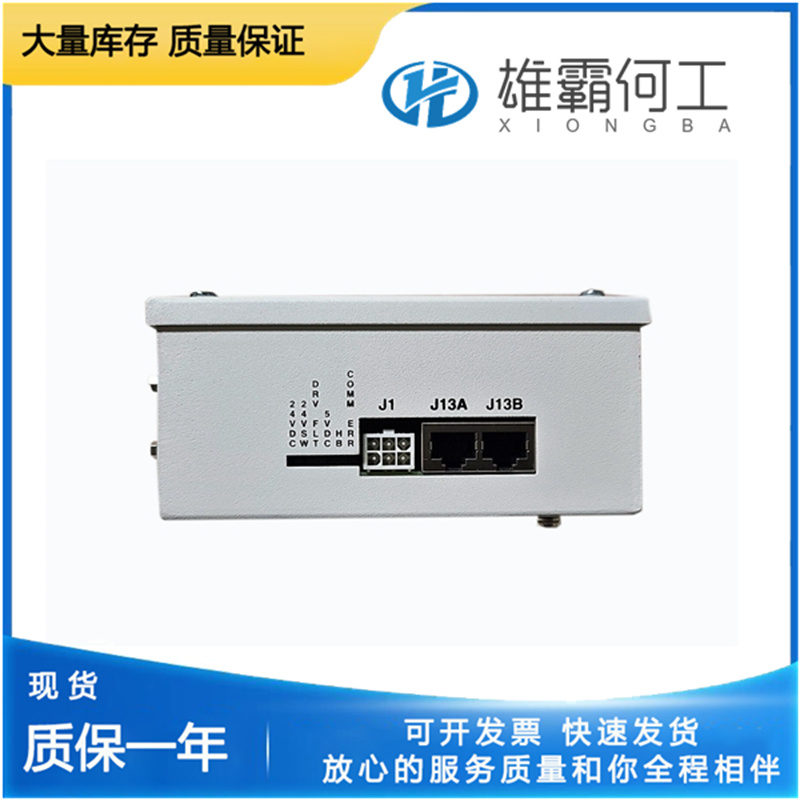

维修工具软件位于PC(个人电脑)上,853-801876-015并通过驱动程序的9针维修端口与ProAct驱动程序通信。各种用户可使用以下模式:出厂校准、测试、配置、用户校准、调整和监控模式(见下图的操作模式)。工厂校准和测试模式是Woodward内部独有的选项;客户可以使用其他所有功能。维修工具模式受密码保护,853-801876-015以防止无意中更改程序。Tune和Monitor功能始终可用,不受密码保护。为了安全起见,853-801876-015只有在机组关闭时才能进入密码保护模式。可以通过维修工具命令或打开低功率待机模式离散输入来关闭机组。