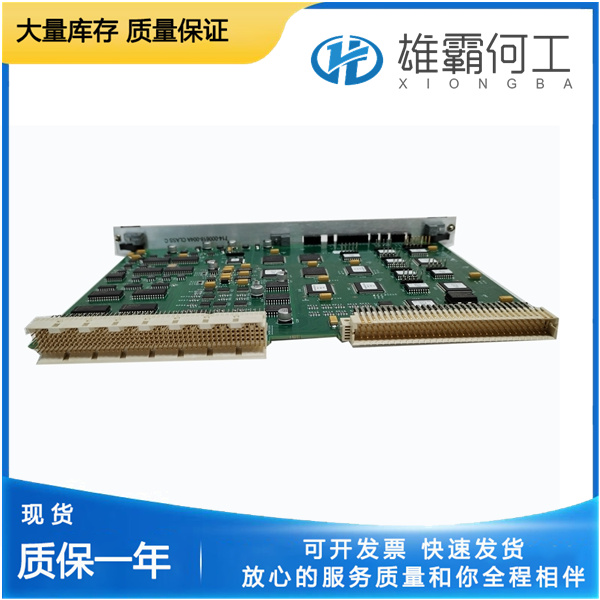

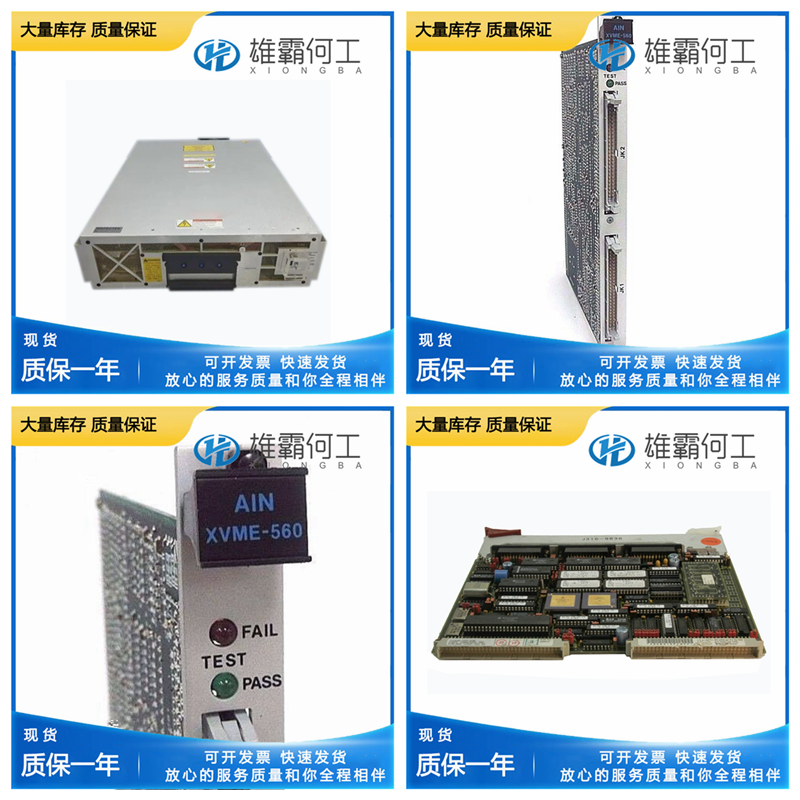

LAM 810-017003-004 集成电路

产品概述:

故障可能是can过慢或can无信号,具体取决于接收到的信息数量。CAN输入故障延迟(秒)默认值=0.3秒(0.1到10)CAN请求信号故障延迟(以秒为单位)。该瞬态电流极限和稳态电流都在最小或最大停止电流极限激活之前主动尝试定位输出——也就是说,在该极限接合之前,电流可能达到瞬态极限,然后是稳态极限。这些设置仅在电流控制器上提供积分限制,因此实际电流可能超过此设置。高于此设置的当前误差与位置误差需求成比例。一旦达到最大(或最小)极限,如果需求继续增加(或减少),电流也将按比例增加。瞬态和稳态电流限制仍然有效——电流不会超过这些限制。需求跟踪误差(%)默认值=15%(1.0到100)当使用冗余需求输入(主和备份)时,需求输入的跟踪误差调整。此设置是在发出跟踪警报之前,控制需求和备用需求之间的最大差值(百分比)。差值必须超过“错误延迟”持续时间的“错误”百分比值才能生成警报。值为“100”将禁用报警。请求跟踪错误延迟(秒)默认值=1秒(0.1到10)跟踪错误延迟,以秒为单位--请参阅请求跟踪错误。

该设置以配置模式中设置的标称频率的百分比表示。如果PWM输入频率在“PwmIn Fail Delay”时间内高于“Fail Max”赫兹水平,则确定为故障。PwmIn Fail Min Duty(%)default=5%(1到50)Duty cycle value(占空比值),在该值PWM输入将被确定为失败。如果PWM输入占空比在“PwmIn Fail Delay”时间内低于“Fail Min”占空比水平,则确定为故障。PwmIn Fail Max Duty(%)default=95%(50到99)Duty cycle value(占空比值),在该值PWM输入将被确定为失败。如果PWM输入占空比在“PwmIn Fail Delay”时间内高于“Fail Max”占空比水平,则确定为故障。

Auto Status—String indication of the automatic user stop procedure. –1= Failed 0 = Disabled 1 = Enabled 2 = Looking for Min Stop 3 = Looking for Max Stop 4 = Stops Set Auto Status Int—Integer indication of the Auto Status string (see above). Manual Enable dflt = false Command to enable the manual user calibration. When true, the Manual Set Position (%) is actively controlling the driver output to the commanded position. This mode can also be used to stroke the output. Manual Set Position (%) default 50 % (–10 to 110) Manual position demand. This demand setting is active when the Manual Mode is enabled. Can be used to both set the stops and to stroke the actuator output. Manual Status—String indication of the manual user stop procedure. –1= Failed 0 = Disabled 1 = Enabled 2 = Min Stop Set 3 = Max Stop Set Manual Status Int—Integer indication of the Manual Status string (see above). Manual—At Min Posn dflt = false (momentary true command only) Command to indicate minimum position is reached. This sets the 0 % (min) position for all position demand signals. Manual—At Max Posn dflt = false (momentary true command only) Command to indicate maximum position is reached. This sets the 100 % (max) position for all position demand signals. Adjusting and Testing Actuator Dynamics Actuator dynamics are set in the Configure Mode, but can also be adjusted in the Adjust User Stop mode. There is only one adjustable dynamics parameter, it is the Actuator Inertia Setting (see Table 9-1).

To change this parameter, the User Stop mode must be enabled. Actuator Inertia Test Execute Once changed, it is recommended the setting be tested. A quick stability check can be done by selecting the ‘Actr Inertia Test Execute’ command. This provides a short actuator positioning sequence and can be used to verify the Inertia Setting. The sequence goes to 30 % travel for 3 seconds, then goes to 70 % for 3 seconds and back to 30 % for 3 seconds, concluding the test. If instability is detected, the test can be aborted by setting the Execute command back to false. In general, if the Inertia Setting is too high the output will have a high frequency oscillation and too low the frequency of oscillation will be much slower or response will be sluggish.

Actuator Inertia Setting dflt =0 (range 0–25) Actuator/valve inertia setting. This setting is available for systems with higher or lower inertia than the default as indicated by excessive shaft movement. A zero (0) setting is basically for an unconnected shaft, whereas, increasing the setting implies a higher inertia in the system. Refer to Table 9-1 for an approximate Inertia Setting value based on lever size. High Friction System dflt =false (false, true) Internal Disturbance Observer Controller (dobs) Enable command. Normally set to false, only needed in high friction systems. As a general rule-of-thumb, when more than 2 A of current are required to move the actuator then a true setting will help with controllability.