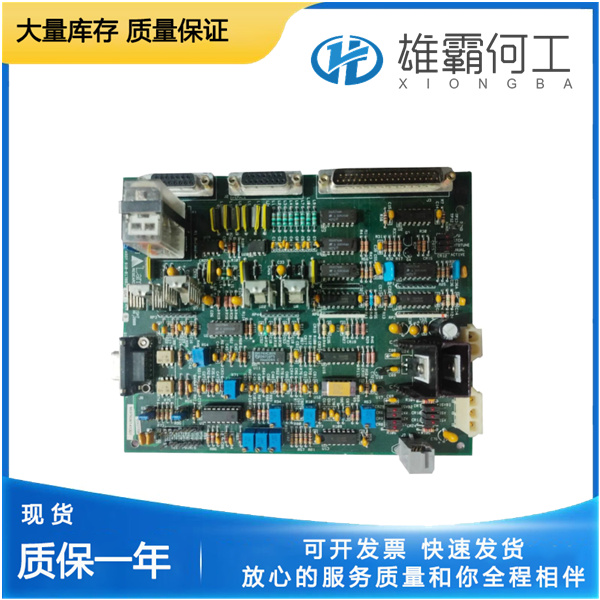

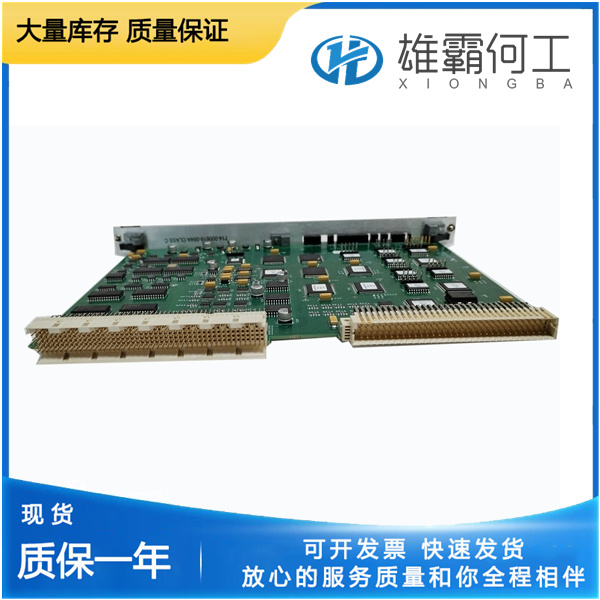

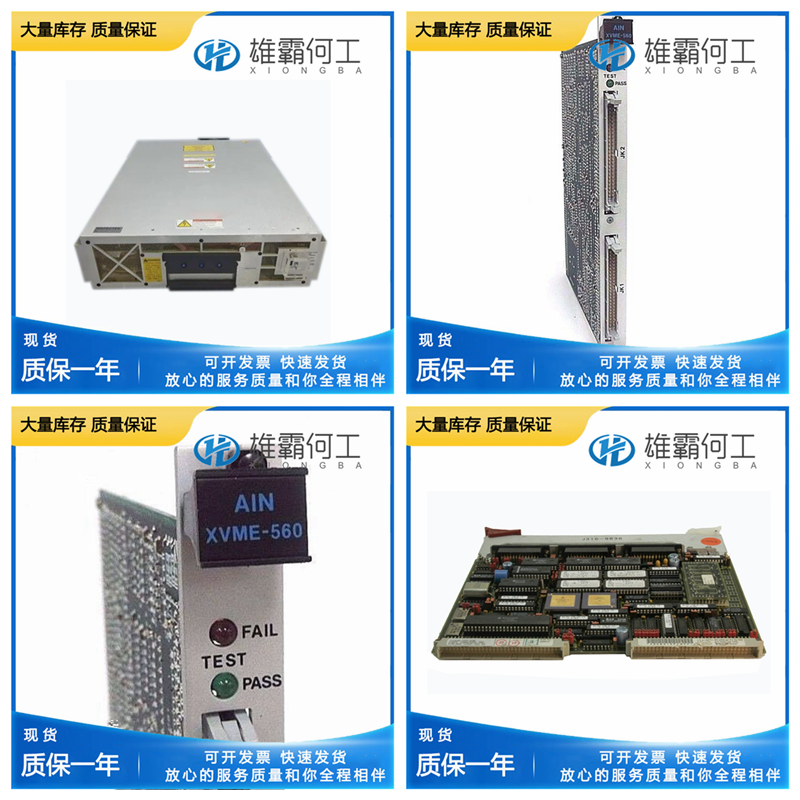

LAM 810-017016-001 半导体

产品概述:

故障可能是can过慢或can无信号,810-017016-001具体取决于接收到的信息数量。CAN输入故障延迟(秒)默认值=0.3秒(0.1到10)CAN请求信号故障延迟(以秒为单位)。该瞬态电流极限和稳态电流都在最小或最大停止电流极限激活之前主动尝试定位输出——也就是说,在该极限接合之前,电流可能达到瞬态极限,然后是稳态极限。这些设置仅在电流控制器上提供积分限制,因此实际电流可能超过此设置。高于此设置的当前误差与位置误差需求成比例。一旦达到最大(或最小)极限,如果需求继续增加(或减少),电流也将按比例增加。瞬态和稳态电流限制仍然有效——电流不会超过这些限制。需求跟踪误差(%)默认值=15%(1.0到100)当使用冗余需求输入(主和备份)时,需求输入的跟踪误差调整。此设置是在发出跟踪警报之前,控制需求和备用需求之间的最大差值(百分比)。810-017016-001差值必须超过“错误延迟”持续时间的“错误”百分比值才能生成警报。值为“100”将禁用报警。810-017016-001请求跟踪错误延迟(秒)默认值=1秒(0.1到10)跟踪错误延迟,以秒为单位--请参阅请求跟踪错误。

每当装置通电并按小时存储时,或如果启用了低功率备用模式离散输入,则时间累积。停机命令使用维修工具强制装置进入停机状态的命令。有助于进入需要关闭装置的模式,如配置或调整用户停止。此命令可以在true和false之间切换。当切换为true时,装置将保持关机状态,810-017016-001直到此参数设置回false或ProAct上的电源循环。810-017016-001Status–报警存在报警条件的一般指示,具体报警条件请参阅Status Error Alarms(状态错误报警)选项卡。Status–Shutdown(状态–停机)表示存在停机条件的一般指示,具体条件请参阅Status Error Shutdows(810-017016-001状态错误停机)选项卡页。

A failure is determined if the PWM input frequency is above the ‘Fail Max’ hertz level for the ‘PwmIn Fail Delay’ time. PwmIn Fail Min Duty (%) default= 5 % (1 to 50) Duty cycle value at which the PWM input will be determined as failed. A failure is determined if the PWM input duty cycle is below the ‘Fail Min’ duty cycle level for the ‘PwmIn Fail Delay’ time.810-017016-001 PwmIn Fail Max Duty (%) default= 95 % (50 to 99) Duty cycle value at which the PWM input will be determined as failed. A failure is determined if the PWM input duty cycle is above the ‘Fail Max’ duty cycle level for the810-017016-001 ‘PwmIn Fail Delay’ time. PwmIn Fail Delay (sec) default = 0.1 sec (0.01 to 10) PWM input failure delay in seconds. PwmIn Filter default = 0.01 (0 to 1) Lag-tau filter adjustment on the PWM input. Stops—Min Stop Bias (deg) default = 0.5 degrees (–10 to 10) Electrical Stop adjustment in degrees of rotation. This is an actuator range adjustment setting for an extra “bias”810-017016-001 when at the minimum output position. This value biases the overall 0 % demand position. When positive,

810-017016-001this setting can help prevent the ProAct control's current driver from driving the actuator into the hard stops (mechanical limits) when the stop is reached by effectively moving the minimum stop position further from the mechanical stops (see also the Current Limit – Min Stop on the Service Hardware Adjustments tab sheet).810-017016-001 Setting this parameter to a negative value will force the output current to drive into the mechanical stop harder to ensure the valve is closed. Refer also to the Adjust User Stops section in the Service Mode.810-017016-001

Stops—Max Stop Bias (deg) default = 0.5 degrees (–10 to 10) Electrical Stop adjustment in degrees of rotation.810-017016-001 This is an actuator range adjustment setting for an extra “bias” when at the maximum output position. This value biases the overall 100 % demand position.810-017016-001 When positive, this setting can help prevent the ProAct control's current driver from driving the actuator into the hard stops (mechanical limits) when the stop is reached by effectively moving the minimum stop position further from the mechanical stops (see also the Current Limit – Max Stop on the Service Hardware Adjustments tab sheet).810-017016-001 Setting this parameter to a negative value will force the output current to drive into the mechanical stop harder to ensure the valve is opened. Refer also to the Adjust User Stops section in the Service Mode.810-017016-001