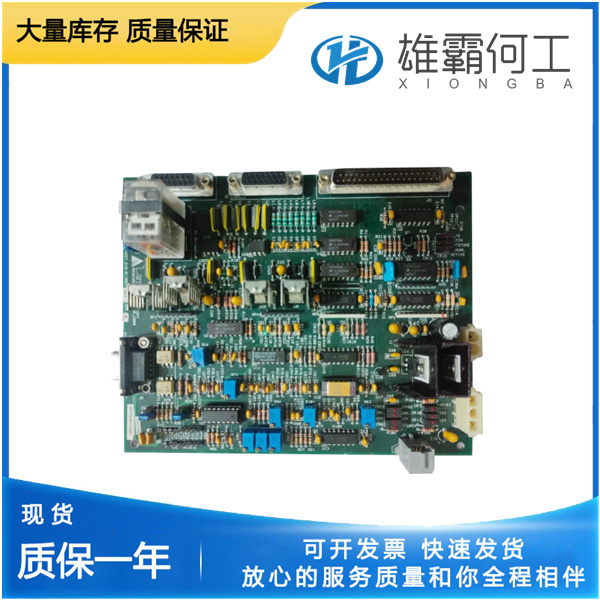

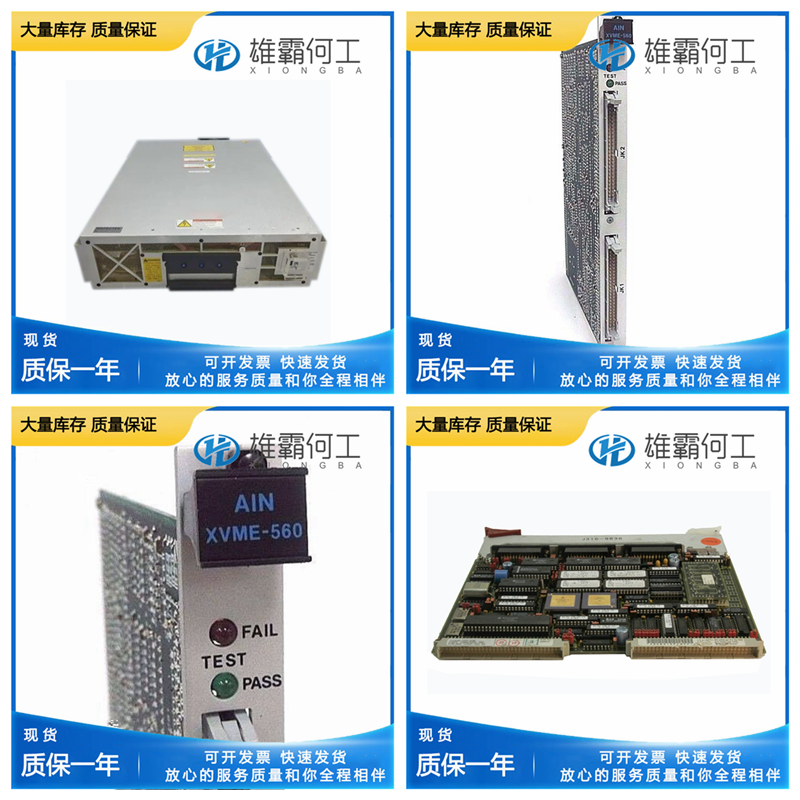

LAM 810-017082-001 集成电路

产品概述:

810-017082-001始终在执行器移动时检查燃油控制连杆的位置。连杆必须自由移动,没有摩擦和齿隙。由于悬挂机构中的迟滞或卡滞,某些燃油控制装置在特定燃油或齿条位置会出现问题。810-017082-001燃油供应和喷油器状况也会出现问题,类似于调速器问题。在火花点火发动机上,分配器、线圈、点和正时问题都可能导致操作不当,这可能类似于调速器控制故障。控制装置可能因电压错误而损坏。更换控制装置时,检查电源、蓄电池等的电压是否正确。810-017082-001故障排除步骤本章是隔离系统故障的一般指南。本指南假定系统接线、焊接连接、开关和继电器触点以及输入和输出连接正确且工作正常。按照指示的顺序进行检查。各种系统检查均假定先前的检查已正确完成。

发动机操作不当通常是调速器操作以外的因素造成的。本章给出了有关发动机问题的提示,这些问题可能类似于调速器问题。在对调速器进行任何更改之前,确保发动机工作正常。810-017082-001以下故障排除指南有助于隔离控制箱、执行器、接线或其他故障。仅当有完整的控制测试设施可用时,建议排除超出此级别的故障。试图纠正调速器调整不及时的发动机或负载问题会使问题变得更严重。如有可能,将调速器与发动机隔离,以确定故障是否出在调速器上,而不是发动机或发动机负载上。调速器故障通常由执行器和发动机之间的安装或连杆故障引起。810-017082-001在对执行器或驱动器进行任何调整之前,仔细检查所有接线连接、电源和连杆。

The linkage must move freely without friction and without backlash. Some fuel controls will present problems at particular fuel or rack positions because of a hesitation or binding in the linkage. Fuel supply and injector conditions can also present problems,810-017082-001 which resemble governor problems. On spark-ignited engines, distributor, coil, points, and timing problems can all cause improper operations, which may resemble faulty governor control. The control can be damaged with the wrong voltage. When replacing a control, check the power supply, battery, etc., for the correct voltage. Troubleshooting Procedure This chapter is a general guide for isolating system problems. The guide assumes that the system wiring,810-017082-001 soldering connections, switch and relay contacts, and input and output connections are correct and in good working order. Make the checks in the order indicated.810-017082-001 Various system checks assume that the prior checks have been properly done.

Improper engine operation is often the result of factors other than governor operation. This chapter gives tips about engine problems, which can resemble governor problems.810-017082-001 Make sure the engine is operating correctly before making any changes in the governor. The following troubleshooting guide is an aid in isolating trouble to the control box, actuator, wiring, or elsewhere.810-017082-001 Troubleshooting beyond this level is recommended ONLY when a complete facility for control testing is available. Attempting to correct engine or load problems with untimely governor adjustment can make problems worse. If possible, isolate the governor from the engine to determine if the problem is with the governor and not with the engine or the load on the engine. Governor faults are usually caused by problems in the installation or the linkage between the actuator and the engine.810-017082-001 Carefully review all the wiring connections, the power supply, and the linkage before making any adjustments to the actuator or driver. Always check the fuelcontrol linkage from stop to stop as if the actuator were moving it.

The integer corresponds to the number in parentheses listed in the Alarm or Shutdown text,810-017082-001 for example ‘PWM No Signal (53)’ is code 53. Entryxx Counter—Number of times the entry has been detected since the last time the log was cleared. Entryxx Time—Time of the first detected occurrence810-017082-001, in hours, relative to how long the unit was running since the last time the log was cleared. The recorded time is based on difference between the RunTime Hours (found under the Unit Status tab sheet) and the ErrorLog Reset Time. For example, if a fault occurs and this is the first occurrence of this fault,810-017082-001 the logged time would be 431— assuming RunTime Hours=641 and ErrorLog Reset Time=210. Another example, if the Entryxx Time was 55 and the Reset Time was 200, the time of occurrence was during RunTime hour 255 810-017082-001