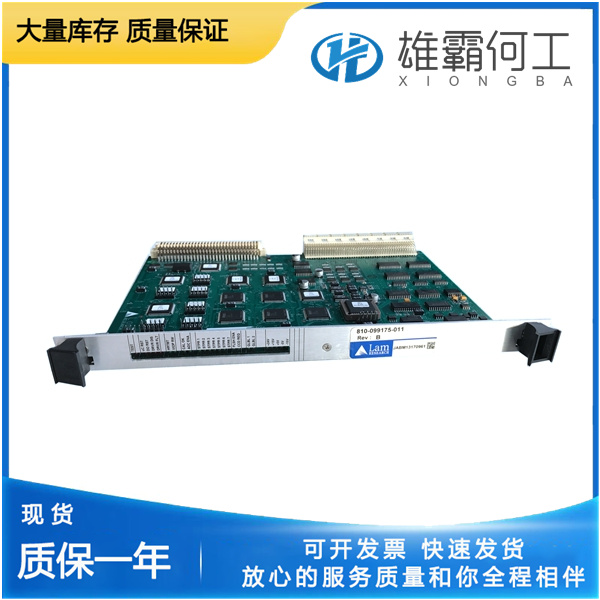

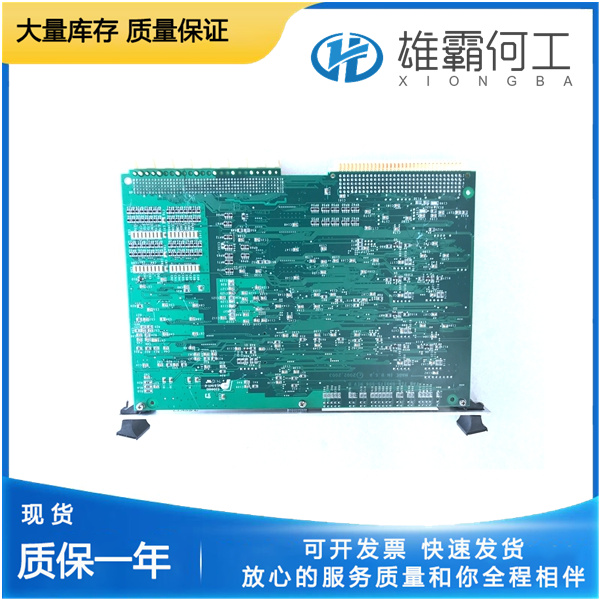

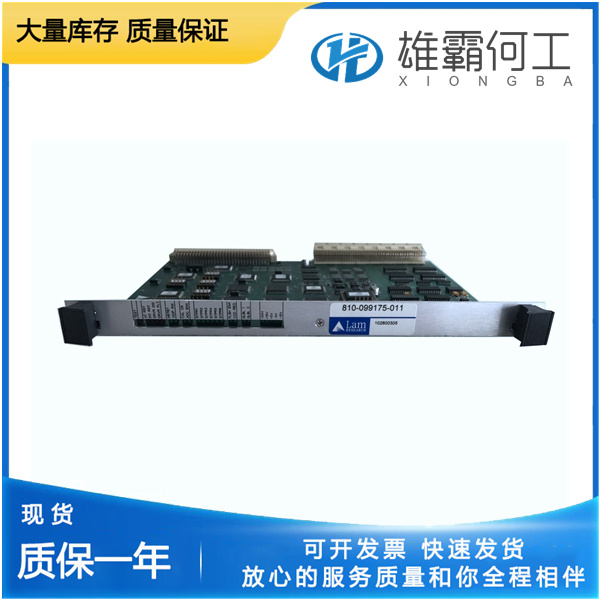

LAM 810-099175-008 接口板模块

产品概述:

在调速器达到最大行程之前,阀门是否完全打开?机械故障排除指南连杆和执行机构行程尽可能多地使用75度的执行机构行程。在进行悬挂机构布置时,请仔细遵循第2章“驾驶员调整”部分中的指南。使用不到最佳的致动器运动将使稳定性更加困难,并将使致动器对外部加载力和摩擦更加敏感。执行机构表现出“摆动”或大的极限循环。检查端子杆是否松动。检查连杆是否松动或磨损。验证安装硬件是否正确。验证安装螺栓是否拧紧至适当的扭矩值。验证惯性设置。无法在无动力状态下旋转独立执行机构内部机械故障——更换执行机构。

通用系统故障排除指南以下是针对可能存在潜在困难的检查区域的通用故障排除指南。在联系Woodward寻求技术帮助之前,通过对您的发动机/涡轮机进行适当的检查,可以更快、更准确地评估您的系统问题。执行机构执行机构接线是否正确?笔划的方向正确吗?(这是使用维修工具配置的。)反馈信号是否已校准?(这是通过维修工具校准的。)是否设置了负载惯性?(这是使用维修工具设置的。)连杆是否有倾斜或空转?是否存在错位、捆绑或侧面装载?是否有可见的磨损或疤痕?悬挂机构是否平稳移动?阀门阀门是否平稳地通过其适当的行程?阀门是否进行全行程?可以获得并保持中冲程吗?调速器达到最小行程之前,阀门是否完全就位(关闭)?

· Using less than optimum actuator movement will make stability more difficult, and will make the actuator more sensitive to external loading forces and friction. Actuator exhibits “hunt” or large limit cycle. Check for loose terminal lever. Check for loose or worn linkage. Verify correct mounting hardware. Verify mounting bolts are tightened to appropriate torque values. Verify inertia setting. Unable to rotate stand alone actuator in unpowered condition Internal mechanical failure—replace actuator.

Is there misalignment, binding, or side loading? Is there visible wear or scarring? Does the linkage move smoothly? Valves Does the valve move through its proper stroke smoothly? Does the valve travel its full stroke? Can mid-stroke be obtained and held? Does the valve fully seat (close) before the governor reaches full minimum stroke? Does the valve fully open before the governor reaches maximum stroke? Mechanical Troubleshooting Guide Linkage and Actuator Stroke Use as much of the 75 degrees of actuator stroke as possible. Carefully follow the guidelines in the Driver Adjustments section of Chapter 2 in making linkage arrangements.

·General System Troubleshooting Guide The following is a general troubleshooting guide for areas to check which may present potential difficulties. By making these checks appropriate to your engine/turbine before contacting Woodward for technical assistance, your system problems can be more quickly and accurately assessed. Actuators Is the actuator wiring correct? Is the direction of the stroke correct? (This is configured using the Service Tool.) Has the feedback signal been calibrated? (This is calibrated through the Service Tool.) Had Load Inertia been set? (This is set using the Service Tool.) Linkage Is there slop or lost motion?