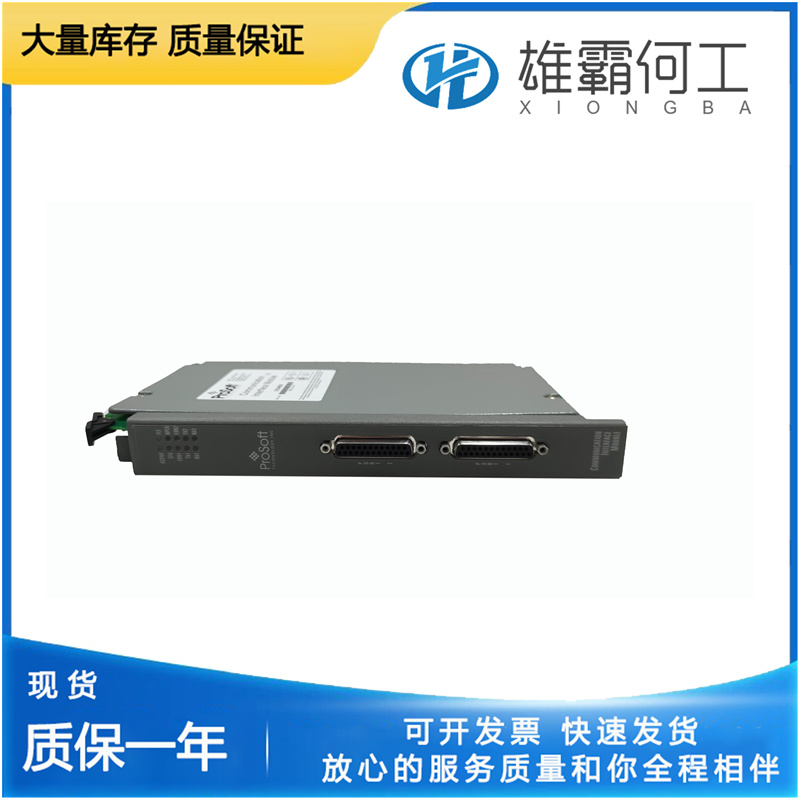

PROSOFT 3100-MCM 通信接口模块

安装前,用浸有矿物精的抹布拆下软密封。存储从我们的工厂收到的UG杠杆调速器可以短时间存储。对于长期储存或在恶劣环境中储存,请遵循3100-MCM(3100-MCM,参考文献)。安装要求UG杠杆调速器的推荐转速范围为375至1500 rpm,可顺时针或逆时针驱动。建议的最大恒定转速为1000至1500转/分,在额定转速和正常工作温度下需要1/3马力(249瓦)。工作温度范围为-40至+220°F(-40至+104°C)。安装调速器之前,确保调速器驱动轴能够自由旋转。使用调速器和原动机驱动器之间正确长度的联轴器,将调速器垂直安装并固定在其安装垫上。确保传动轴没有卡滞、侧面负载过大或联轴器没有松动。不得有任何力将驱动轴推入调速器。h允许发动机通过节气门关闭

3100-MCM杠杆是一种机械液压调速器,用于控制双燃料或柴油发动机或蒸汽轮机。UG操纵杆与燃油架或燃油阀机械连接并操作,具体取决于系统。输出轴(终端轴)的最大行程为42°。输出轴的建议行程约为从空载到满载的可用行程的2/3,这允许在每一端都有足够的超程,以便调速器可以产生停机,并在需要时提供最大的燃料(见图1-1)。正常情况下,UG操纵杆同步运行(恒定速度),不考虑发动机上的负载,除非在瞬态负载条件下。操作的细节在第3章“操作原理”中进行了描述。降速也可作为UG杠杆调速器上的一种特殊辅助装置,用于在驱动同一轴的装置之间分配和平衡负载。3100-MCM杠杆调速器也可以配备一个停机杆

当您收到UG杠杆调速器时,它将被螺栓固定在垂直位置的木制平台上。在工厂测试调速器后,将其排油。这会在内部零件上留下一层薄薄的油膜,防止生锈。安装前无需进行内部清洁。一些驱动轴喷有一层薄薄的油膜,而另一些(取决于客户要求)则覆盖有软密封。

When you receive your UG Lever governor, it will be bolted to a 3100-MCMplatform in the vertical position. After testing the governor at the factory, it is drained of oil. This leaves a light film of oil covering the internal parts, preventing rust. No internal cleaning is required before installation. Some drive shafts are sprayed with a light film of oil while others (depending on customer requirements) are covered with soft seal. Before installation, remove the soft seal with a rag saturated with mineral spirits. Storage The UG Lever governor may be stored for short periods of time as received from our factory. For prolonged storage or storage in a hostile environment, follow instructions given in 3100-MCMmanual 3100-MCM(see Chapter 1, References).

The UG Lever is 3100-MCM a mechanical-hydraulic governor for controlling dual fuel or diesel engines or steam turbines. The UG Lever is mechanically linked to and operates the fuel racks or fuel valves, depending on the system. The maximum travel of the output shaft (terminal shaft) is 42°. Recommended travel of the output shaft is approximately 2/3 of available travel from no load to full load, which allows sufficient overtravel at each end so that the governor can create a shutdown and also give maximum fuel when required (see Figure 1-1). Normally, the UG Lever operates isochronously (constant speed) regardless of load on the engine except during transient load conditions. Details of the operation are described in Chapter 3, Principles of Operation. Speed droop is also available as a special auxiliary on the 3100-MCMLever governor to divide and balance load between units driving the same shaft. The UG Lever governor can also be equipped with a shutdown rod whic

The 3100-MCMLever is a mechanical-hydraulic governor for controlling dual fuel or diesel engines or steam turbines. The UG Lever is mechanically linked to and operates the fuel racks or fuel valves, depending on the system. The maximum travel of the output shaft (terminal shaft) is 42°. Recommended travel of the output shaft is approximately 2/3 of available travel from no load to full load, which allows sufficient overtravel at each end so that the governor can create a shutdown and also give maximum fuel when required (see Figure 1-1). Normally, the 3100-MCMLever operates isochronously (constant speed) regardless of load on the engine except during transient load conditions. Details of the operation are described in Chapter 3, Principles of Operation. Speed droop is also available as a special auxiliary on the UG Lever governor to divide and balance load between units driving the same shaft. The UG Lever governor can also be equipped with a shutdown rod which allows the engine to be shut down from the throttle