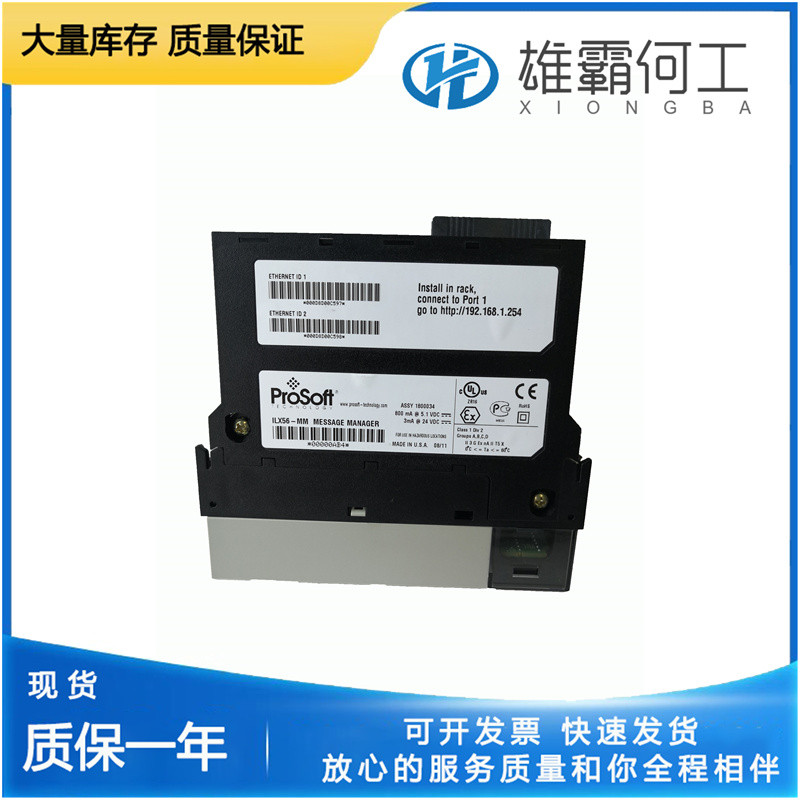

PROSOFT ILX56-MM 通信模块

经过修理或重新组装的调速器的初始操作在拆卸或修理后,在试验台上测试调速器是非常重要的。如果没有测试台,可以在发动机上进行调速器测试。如果在发动机上测试调速器,请小心手动控制发动机转速,直到您证明调速器可以控制发动机转速。除了将普通连杆连接到输出轴上外,还将一把锯齿扳手连接到输出上,以便用锯齿扳手手动控制发动机转速。当确信调节系统完全工作时,拆下锯齿扳手。在第一次操作维修后的调速器之前,检查所有安装步骤是否已正确完成(见第2章)。也请阅读本章的全部内容。

从该设置开始,打开针阀一圈,然后手动干扰调速器燃油设置。逐渐关闭针阀,直到调速器恢复到只有一个小的过冲或下冲的速度,并且:a.针阀在调速器上打开1/8到1/4圈,调速器上的油视镜位于表盘的中心。b.在调速器上,针阀在3/8到3/4转之间打开,调速器侧面有一个油视镜。补偿调整决定关闭速度,针阀调整决定恢复时间。对于最灵敏的调速器控制,使用尽可能少的补偿。补偿过多会导致负载变化时出现过多的速度过冲和欠冲。关闭针阀的次数超过上述a.或b.中所示的次数,会使调速器在负载变化后缓慢恢复到正常速度。打开针阀的次数超过上述指示会降低调速器的稳定性,并可能导致振荡。一旦针阀调整正确,则无需更改设置,除非温度发生较大的永久性变化,从而影响调速器油粘度。调整正确后,拧紧补偿指针螺母,然后用铜垫圈重新安装针阀检修塞。塞子和垫圈将密封针阀周围的漏油。

If a test stand is not available, testing of the governor can be done on the engine. If testing of the governor is done on the engine, be careful to manually control the engine speed until your have proven that the governor will control engine speed. Attach a serration wrench to the output shaft in addition to the normal linkage to manually control engine speed with the serration wrench. When satisfied that the governing system is fully operative, remove the serration wrench. Before operating a repaired governor for the first time, check that all installation steps have been correctly completed (see Chapter 2). Also read all of this chapter.

Closing the needle valve more than indicated in a. or b. above makes the governor slow to return to normal speed after a load change. Opening the needle valve more than indicated above decreases governor stability and can cause hunting. Once the needle valve adjustment is correct, it is not necessary to change the setting except for large, permanent changes in temperature which affect governor oil viscosity. When the adjustment is correct, tighten the compensation pointer nut and reinstall the needle valve access plug with a copper washer. The plug and the washer will seal oil seepage around the needle valve. Initial Operation for a Repaired or Reassembled Governor After disassembly or repair, it is very important to test the governor on a test stand.

From this setting, open the needle valve one turn and manually disturb the governor fuel setting. Gradually close the needle valve until the governor returns to speed with only a small overshoot or undershoot and: a. The needle valve is between 1/8 to 1/4 turn open on a governor with an oil sight glass located in the center of the dial panel. b. The needle valve is between 3/8 to 3/4 turn open on a governor with an oil sight glass located on the side of the governor. Compensation adjustment determines off-speed, and needle valve adjustment determines recovery time. For most responsive governor control, use as little compensation as possible. Too much compensation causes excessive speed overshoots and undershoots on load changes.