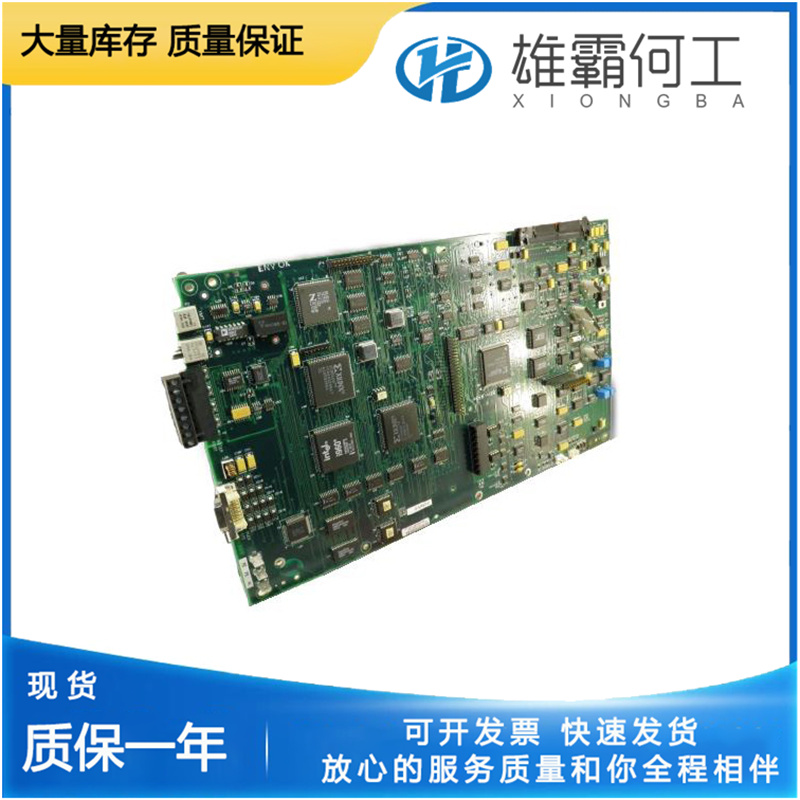

RELANCE 10V4160 用作稳压板

投用时,应该对模件地址和其他开关设定,并监护人确认后,方可插入正确的模位,并填写记录卡。 4、定期检查 应每半年对工厂库房保存的各种少量DCS系统常用备件进行检查,检查内容如下: 1)表面清洁、印刷板插件无油渍,印刷板插件无油渍,轻微敲击后无异常。 2)软件装卸试验正常,通信口、手操站工作正常。 3)各种模拟量、开关量输入、输出通道工作正常。 4)装入测试软件,正常工作不少于48h以上。 5)冗余模件的切换试验。 6)检查后应填写检查记录,并粘上合格标志。

在DCS系统的使用过程中,对于DCS备件的管理工作是很重要的,DL/T774-2001《火力发电厂分散控制系统运行检修导则》中提出了对于DCS备件管理的要求,正确管理DCS备件涉及存放要求、定期检查、使用前准备、使用时等四个方面内容,具体要求如下: 1、存放要求 DCS系统备用模件存放应满足的要求为:各种模件必须用防静电袋包装后存放或根据制造厂的要求存放,模件存贮室的温度、湿度也应满足制造厂的要求;存取模件时应采取防静电措施,禁止任何时候用手触摸电路板,并且进行登记,办理进、出库手续。 2、用前准备 运行前必须检查各通信口、I/O功能、控制算法功能是否满足要求;在工程师站上对模件状态进行检查符合要求;在模件内装入组态,检查是否正确。

According to the characteristics of computer control equipment, in addition to peripheral equipment maintenance like conventional control equipment, DCS random group size maintenance should at least carry out the following items of maintenance: copy of module configuration, verification of control module flags and addresses; Clean the power supply, modules, and dust filter, check and tighten the wiring of the control cabinet, conduct grounding system inspection, cooling fan maintenance, and power equipment maintenance and testing; Insulation inspection of important measurement and protection signal lines; Test the temperature, humidity, and dust content of the electronic room before maintenance, and recheck it after maintenance; Switching test of module power supply and redundant modules; Alarm and protection function testing; Inspection of communication and manual operation stations; Perform card verification, etc; Before maintenance, sufficient preparation work should be done. During maintenance, the process card system should be strictly followed, and maintenance records should be carefully kept. Test reports for power supplies, modules, and other components should be carefully filled out.

With the widespread application of DCS in large thermal power plants, determining the maintenance content, maintenance cycle, and maintenance items of DCS is the key to ensuring its safe operation under the application conditions of thermal power plants and improving its reliability. In practical applications, the self diagnosis function of computer systems should be fully utilized to detect abnormal situations early and prevent module failures; During maintenance, there should also be a reasonable maintenance process and procedure, taking into account the maintenance of DCS itself and the importance of external equipment maintenance of the control system. Maintenance precautions should be listed according to the characteristics of the DCS system, and certain protective measures should be taken to avoid damage to the DCS device modules during maintenance.

The pressure of the regulating valve instrument air source is low or all instrument air is cut off

When multiple self regulating systems are found to be malfunctioning and the self regulating valve position on the monitoring screen is in the fully open or fully closed position, immediately check the instrument air source pressure. If the air source pressure is less than 0.4MPa, it is abnormal. Check whether the air source pipeline is blocked or leaking; If the gas source pressure is less than 0.2MPa, immediately perform an emergency stop. Turn all the self adjustment systems on the monitoring screen to manual mode, adjust the valve position of the regulating valve to a safe position, notify the instrument worker to check the air source, and at the same time, go to the site for operation. Close the shut-off valves at both ends of the regulating valve and operate it with a bypass valve.