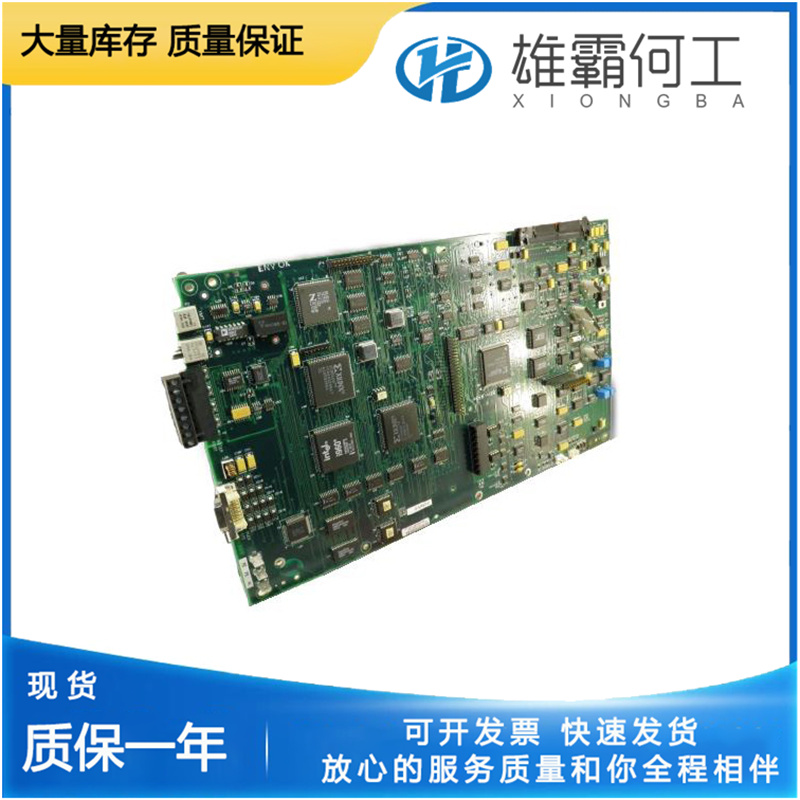

RELANCE 2SR40700 伺服驱动器

故障维维护 系统在发生故障后应进行被动性维护,主要包括以下工作: 3.3.1 专业性维护 一般需厂商或厂家指定的维护工程师来进行维护。

用户一般性维护 系统使用者自身进行的日常维护,维护人员应对系统维护技术难度和可操作性有一定的认识,了解应具备的维护工具,明确哪些工作能自己完成,做到心中 有数,出现问题要及时制定可行的维护方案。对DCS系统故障维护的关键是快速、准确地判断出故障点的位置,故障维护中的一些经验总结如下下几点:

1) DCS系统往往具有丰富的自诊断功能。根据报警,可以直接找到故障点,并且还可通过报警的消除来验证维修结果。

2) 通信接头接触不良会引起通信故障,确认通信接头接触不良后,可以利用工具重做接头;通信线破损应及时更换。

3) 某个卡件故障灯闪烁或者卡件上全部数据都为零,可能的原因是组态信息有错、卡件处于备用状态而冗余端子连接线未接、卡件本身故障、该槽位没有组态信息等。

当某一生产状态异常或报警时,我们可以先找到反映此状态的仪表,然后顺着信号向上传递的方向,用仪器逐一检查信号的正误,直到查出故障所在。

当出现较大规模的硬件故障时,最大的可能是由于DCS系统环境维护不力而造成的系统运故障,除当时采取紧急备件更换和系统清扫工作外,还要及时和厂家取得联系,由厂家专业技术支持工程师进一步确认和排除故障。

结束语对于DCS系统的维护工作,关键是要做到预防第一,作为系统维护人员应根据系统配置和生产设备控制情况,制定科学、合理、可行的维护策略和方式方法,做到预防性维护、日常维护紧密配合,进行系统的、有计划的、定期的维护,保证系统在要求的环境下长期良好地运行,使生产过程控制平稳、运行稳定,为实 现生产和效益的目标,提供可靠保证

After a malfunction occurs, the fault maintenance system should undergo passive maintenance, mainly including the following tasks: 3.3.1 Professional maintenance generally requires the manufacturer or a maintenance engineer designated by the manufacturer to carry out maintenance.

3.3.2 General Maintenance of Users The daily maintenance carried out by the system users themselves should have a certain understanding of the technical difficulty and operability of system maintenance, understand the maintenance tools that should be available, clarify which tasks can be completed on their own, and have a clear understanding. If problems arise, feasible maintenance plans should be formulated in a timely manner. The key to maintaining DCS system faults is to quickly and accurately determine the location of the fault point. Some experiences in fault maintenance can be summarized as follows:

DCS systems often have rich self diagnostic functions. Based on the alarm, the fault point can be directly identified, and the maintenance results can also be verified by eliminating the alarm.

2) Poor contact of communication connectors can cause communication faults. After confirming poor contact of communication connectors, tools can be used to redo the connectors; If the communication line is damaged, it should be replaced in a timely manner.

3) The flashing fault light of a certain card or all data on the card being zero may be due to incorrect configuration information, the card being in a standby state with redundant terminal connection wires not connected, the card itself malfunctioning, or the lack of configuration information in that slot.

When a certain production status is abnormal or an alarm occurs, we can first find the instrument that reflects this status, and then use the instrument to check the correctness of the signal one by one along the direction of signal transmission until the fault is identified.

When a large-scale hardware failure occurs, the most likely cause is the system operation failure due to poor maintenance of the DCS system environment. In addition to emergency spare parts replacement and system cleaning work, it is also necessary to contact the manufacturer in a timely manner, and have the manufacturer's professional technical support engineer further confirm and eliminate the fault.

Conclusion: For the maintenance work of DCS system, the key is to prioritize prevention. As system maintenance personnel, they should develop scientific, reasonable, and feasible maintenance strategies and methods based on system configuration and production equipment control, achieve close coordination between preventive maintenance and daily maintenance, and carry out systematic, planned, and regular maintenance to ensure that the system operates well in the required environment for a long time, ensuring smooth production process control Stable operation, providing reliable assurance for achieving production and efficiency goals