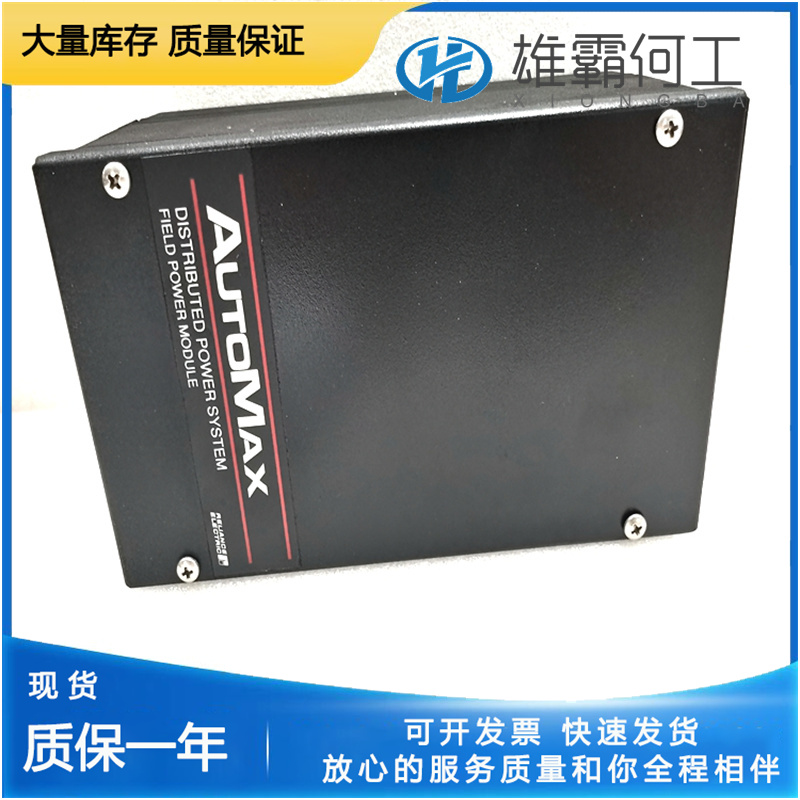

RELANCE 45C922 板子模块卡件

系统上电及测试

(1)启动工程师站、服务器站、操作站、同时将系统各电源箱依次上电检查。

(2)检查各电源箱是否工作正常,电源风扇是否工作,5V、24V指示灯是否正常。

(3)检查各计算机的系统软件及应用软件的文件夹和文件是否正确;硬盘剩余空间无较大变化,并通过磁盘表面测试。

(4)将修改后的组态进行编译下载。

(5)从每个操作站实时监控的故障诊断中观察是否存在故障。

(6)打开控制站柜门,观察卡件是否工作正常,有无故障显示(FAIL灯亮)。

(7)供电冗余测试

分别开通冗余交流~220VAC总进线的一路,其他交流供电回路失电,但系统应仍然可以正常工作。

分别开通冗余直流电源一路,关闭其他直流电源,测量每一机笼(架)母板电源端子上5V、24V的电压。

(8)通信冗余测试:分别接通各冗余通讯线的其中一路通讯线(其他通讯线脱开),利用下载组态功能测试是否正常,如均正常则表明通讯网络正常。

(9)卡件冗余测试:通过带电插拔互为冗余的卡件,检查冗余是否正常。

注意:如果拨出冗余的主控卡、数据转发卡的其中一块并插回后,须等数据拷贝完成后才可拨另一块冗余卡,否则在生产过程中会造成严重后果。

进行DCS停电维护

(1)操作站、控制站停电吹扫检修。包括工控机内部,控制站机笼、电源箱等部件的灰尘清理。

(2)针对日常巡检、定期巡检中发现而不能及时处理的故障进行维护及排除。

(3)仪表及线路检修:包括供电线路、I/O信号线、通讯线、端子排、继电器、安全栅等。确保各仪表工作正常,线路可靠连接,标识清晰正确。

(4)接地系统检修。包括端子检查、各操作站(工控机、显示器)接地检查、各控制站(电源、机笼)接地检查、对地电阻测试。

第四步:现场以及DCS的各项维护工作完成后,检查确认以下各项重新上电条件是否满足

(1)首先应联系工艺、电气、设备、仪表等专业共同确认是否满足DCS系统的上电条件。

(2)确认电气提供的总电源符合要求后,合上供电总断路器,并分别检查输出电压。

(3)合上配电箱内的各支路断路器,分别检查输出电压。

(4)若配有UPS或稳压电源,检查UPS或稳压电源输出电压是否正常。

Before use, it is necessary to check whether the communication ports, I/O functions, and control algorithm functions meet the requirements before running; Check the module status on the engineer station to ensure it meets the requirements; Load the configuration into the module and check if it is correct. 3. When put into use, the module address and other switches should be set and confirmed by the guardian before inserting the correct module position and filling out the record card. 4. Regular inspections should be conducted every six months on various small quantities of commonly used DCS system spare parts stored in the factory warehouse. The inspection contents are as follows: 1) Surface cleaning, no oil stains on the printed board plug-in, no oil stains on the printed board plug-in, and no abnormalities after slight tapping.

In the use of DCS systems, the management of DCS spare parts is very important. DL/T774-2001 "Guidelines for Operation and Maintenance of Distributed Control Systems in Thermal Power Plants" proposes requirements for DCS spare parts management. Correct management of DCS spare parts involves four aspects: storage requirements, regular inspections, preparation before use, and use. The specific requirements are as follows: 1 The storage requirements for backup modules in the DCS system include: all modules must be packaged in anti-static bags for storage or stored according to the manufacturer's requirements, and the temperature and humidity in the module storage room should also meet the manufacturer's requirements; When accessing modules, anti-static measures should be taken. It is prohibited to touch the circuit board with hands at any time, and registration should be carried out to handle incoming and outgoing procedures.

Minor repair projects

The DCS system minor maintenance shall be carried out along with the unit minor maintenance, and the minor maintenance items shall include the following contents:

1) Clean the dust-proof filter screen of the cabinet and inspect various cooling fans.

2) Check the working status of the power supply and modules.

3) Hardware device function test.

4) Eliminate defects that cannot be handled during operation.

5) Partial on-site equipment maintenance; Partial I/O module verification.

6) Main protection and interlocking test of the unit.