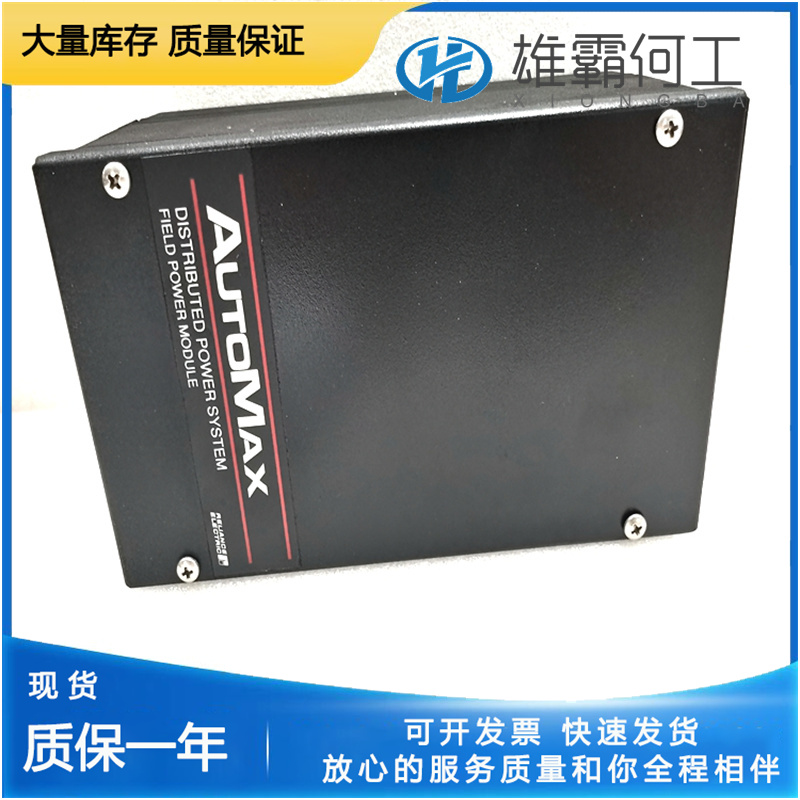

RELANCE 57552-4 伺服驱动器

软件报错,如何处理?

软件组态与硬件协调有误出现的问题

数据库点组态与对应通道连接的现场信号不匹配;

鼠标驱动程序加在COM1口,造成系统在线运行时不能用鼠标操作;

打印机不打印等等。

5、连线接头改注意哪些问题?

连线接头问题

连接头没有采用压焊或焊接不好造成虚焊;

热循环使接头松动;

螺栓连接点因震动引起松动;

连接点因腐蚀而接触不良。

当某一生产状态异常或报警时,我们可以先找到反映此状态的仪表,然后顺着信号向上传递的方向,用仪器逐一检查信号的正误,直到查出故障所在。

当出现较大规模的硬件故障时,最大的可能是由于DCS系统环境维护不力而造成的系统运故障,除当时采取紧急备件更换和系统清扫工作外,还要及时和厂家取得联系,由厂家专业技术支持工程师进一步确认和排除故障。

结束语对于DCS系统的维护工作,关键是要做到预防第一,作为系统维护人员应根据系统配置和生产设备控制情况,制定科学、合理、可行的维护策略和方式方法,做到预防性维护、日常维护紧密配合,进行系统的、有计划的、定期的维护,保证系统在要求的环境下长期良好地运行,使生产过程控制平稳、运行稳定,为实 现生产和效益的目标,提供可靠保证

After a malfunction occurs, the fault maintenance system should undergo passive maintenance, mainly including the following tasks: 3.3.1 Professional maintenance generally requires the manufacturer or a maintenance engineer designated by the manufacturer to carry out maintenance.

3.3.2 General Maintenance of Users The daily maintenance carried out by the system users themselves should have a certain understanding of the technical difficulty and operability of system maintenance, understand the maintenance tools that should be available, clarify which tasks can be completed on their own, and have a clear understanding. If problems arise, feasible maintenance plans should be formulated in a timely manner. The key to maintaining DCS system faults is to quickly and accurately determine the location of the fault point. Some experiences in fault maintenance can be summarized as follows:

DCS systems often have rich self diagnostic functions. Based on the alarm, the fault point can be directly identified, and the maintenance results can also be verified by eliminating the alarm.

2) Poor contact of communication connectors can cause communication faults. After confirming poor contact of communication connectors, tools can be used to redo the connectors; If the communication line is damaged, it should be replaced in a timely manner.

3) The flashing fault light of a certain card or all data on the card being zero may be due to incorrect configuration information, the card being in a standby state with redundant terminal connection wires not connected, the card itself malfunctioning, or the lack of configuration information in that slot.

During maintenance, the power supply and grounding systems should be checked to ensure they meet the requirements.

(6) Timely maintain DCS maintenance records during major repairs.

2. System maintenance steps during major repairs

Step 1: Check the proofreading backup

Check if the software backup, configuration file backup, control and process data backup are correct and complete.

Step 2: Cut off the power supply in the following order

(1) After each operation station exits the real-time monitoring and operating system in sequence, turn off the power to the industrial control computer and display of the operation station;