RELANCE 57C403 模块化单元

项目概况: 二尿DCS集散控制系统原为JX-300X系统,操作站采用DELL PC微机,操作系统为windows NT系统,应用系统为浙大JX-300X 3.10软件。 升级改造前该系统面临的问题:1、系统稳定性差,控制站故障高,经常出现卡件不能通讯不能正常工作。2、操作站原为DELL微机以超出服务期,微机配件市场已经买不到,而二尿操作站微机有一台主板以坏无法修复,其它3台微机也不同程度出现死机、通讯不畅等故障,严重影响着尿素控制的正常操作。3、新够进DELL微机又不支持浙大原有NT操作系统和JX-300X 3.10软件,面临着旧微机无配件、新微机装不上原有软件的困境。4、一旦操作站另外三台微机出现故障损坏,尿素系统将面临停车的危险。 在种种原因下,为了保证DCS系统的正常运行,而不致于影响尿素生产,经研究并做了充足的试验后决定对原有DCS集散控制系统进行升级改造,将各操作站装成windows 2000系统,和浙大V3.16系统,并将2个控制站也做相应的升级改造,有效地解决了原来存在的问题,为尿素的稳定运行打下了坚实的基础。 升级前我们联系过浙大中控,如来工程师帮助升级,需我们支付包括技术服务费、工程师差路费等在内等7万元,以及所需软件费及配件费3万元,共计十万余元,我们决定自己进行升级,尽可能的为化肥厂节约费用,直接经济效益为化肥厂节约10万余元,间接经济效益因不升级将造成DCS系统无法工作,操作站无法使用,面临着尿素停车的危险,升级避免了此危险的发生,不可小视。

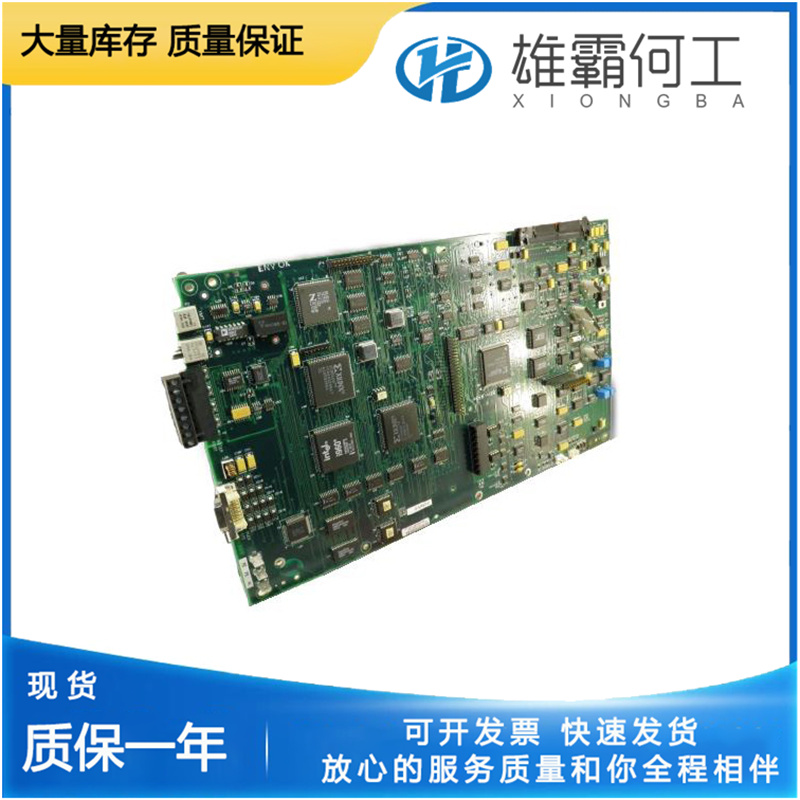

根据计算机控制设备特点,DCS除像常规控制设备一样进行外围设备检修外,随机组大小修至少要进行以下项目的检修,即模件组态拷贝,核实控制模件标志和地址;清扫电源、模件及防尘滤网,检查紧固控制柜接线,进行接地系统检查,冷却风扇检修,电源设备检修测试;重要测量和保护信号线路绝缘检查;电子室温度、湿度及含尘量检修前测试,检修后复查;模件电源及冗余模件的切换试验;报警及保护功能测试;通信、手动操作站检查;进行卡进行校验等;检修前要做好充分的准备工作,检修中要严格执行工序卡制度,并认真做好检修记录,对电源、模件等测试要仔细填写测试报告。

Use a network tester to test whether the network cable hardware is working properly and check if the switch indicator lights are working properly. 2. Check if there are any fault prompts on the monitoring "fault diagnosis" screen. 3. Use the "ping" command on each computer to check if the network is functioning properly and if the IP settings are correct. 4. Check if the network card flow control is turned off and if the network card driver installation is normal. 5. Use the built-in SCDIAGNOSE software in the configuration software to detect network conditions. Q7: How to do a good job of anti-static in DCS system maintenance? A: If maintenance is not done carefully, static electricity may have a significant impact on DCS cards or communication. During DCS maintenance, especially when touching hardware cards or communication components, the following measures should be taken to prevent static electricity. 1. Maintain a certain level of humidity in the environment. In particularly northern regions or in dry winter, the occurrence of malfunctions caused by static electricity is much greater than in southeastern coastal areas or other seasons.

After each operation station exits the real-time monitoring and operating system in sequence, turn off the power to the industrial control computer and display of the operation station;

(2) Turn off the power supply of the control station power box one by one;

(3) Turn off the power switches of each branch;

(4) Turn off the uninterruptible power supply (UPS) switch;Turn off the main power switch

Step 3: Perform DCS power outage maintenancePower outage, blowing and maintenance of operation and control stations. Dust cleaning of components such as the internal control computer, control station cage, and power box.

Maintain and troubleshoot faults found during daily and regular inspections that cannot be promptly addressed.

Instrument and circuit maintenance: including power supply lines, I/O signal lines, communication lines, terminal blocks, relays, safety barriers, etc. Ensure that all instruments are working properly, the wiring is reliably connected, and the markings are clear and correct.

Grounding system maintenance. Including terminal inspection, grounding inspection of each operating station (industrial computer, display), grounding inspection of each control station (power supply, machine cage), and ground resistance testing